EPC Project of Utility System of Desalination (SWRO)

KLIEN

LOKASI

KATEGORI PROYEK

DURASI PROYEK

NILAI PROYEK

EPC Project of Utility System of Desalination (SWRO)

The object of this project is to develop a utility system to support sea water desalination plant (Sea Water Reverse Osmosis, SWRO) at the Sea Water Intake System (SWIS) in AMNT.

Scope :

- Fresh water storage tank with capacity 2,500 MT

- Pumping system, including electric power supply & instrumentation

- 12” and 14” HDPE pipelines for sea water, brine and fresh water

- Civil concrete structure, containment, and drainage system

- Electrical panels & cable trays

- Lighting system

This project functions to supply sea water to the desalination plant located at the SWIS area. It also transfers fresh/product water to a freshwater storage tank and discharges brine water to the sea wall connected to the tailing line. The pumping station is equipped with a redundancy configuration and is installed within SWIS desalination plant area.

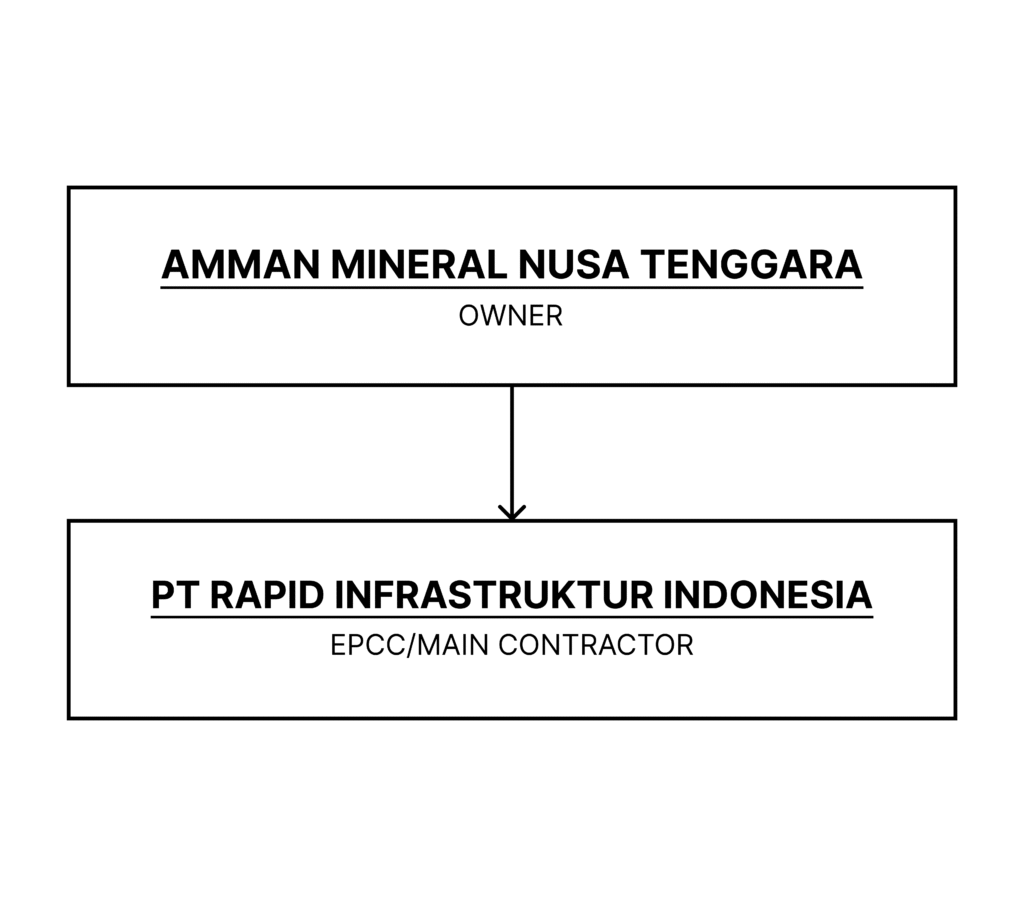

Stakeholder

2 Units Sea Water Pump cap. 720 m3/hr

2 Units Brine Water Pump cap. 418 m3/hr

2 Units Fresh Water Pump cap. 309 m3/hr

1 Unit Fresh Water Tank: Atmospheric Tank, Conical Roof, Carbon steel, Dia 18.3m, H 9.9m, 2500 MT

- Sea Water Pipe: 14” HDPE Pipe PN 12.5, L 880 m

- Brine Water Pipe: 12” HDPE Pipe PN 16, L 800 m

- Fresh Water Pipe: 12” HDPE Pipe PN 16, L 4.500m

1 Ea Fresh Water Tank Foundation

6 Ea Pump Foundation

3 Ea Trafo Shelter

1 Ea Pump Shelter

5 Ea Cable Duct Bank

- Main Power Cable: 33 kV 3x95mm2, total length 1.300 m

- Trafo: 2 x 2 MVA

- Control Cable (FO)

- Switch Room

- MCC

- Lighting, Lightening and Grounding

- Control Valves

Painting system, Marine Environment

DFT 860 micron

6” Electrical Power Cable 33kV Armored with HDPE Sleeve Protection

SPECIFICATION HIGHLIGHTS

Polyurethane, Corro coat

Epoxy

Epoxy

FOTO PROYEK

BORE PILE FACILITY

INSTALATION OF REBAR

TOOLBOX MEETING

PIPE WELDING

WELL INSPECTION

PIPE LINEUP

PT RAPID INFRASTRUKTUR INDONESIA

Talavera Office Park, Lt.12, Jl. TB Simatupang Kav. 22-26, Cilandak Barat, Kec. Cilandak, Kota Jakarta Selatan, DKI Jakarta (14430)